Welcome to Claudius Peters.

Claudius Peters Projects GmbH is headquartered in Buxtehude, Hamburg with regional offices in the Americas, Europe, China and the Far East. Claudius Peters stockyards, pneumatic conveyors, silos, clinker coolers, grinding mills, and packing systems can be found in Cement, Coal, Alumina, and Gypsum plants across the globe. The group’s other principal Division, Aerospace, manufactures aircraft parts for Airbus.

Market Sectors

Swipe to see all sectors

Claudius Peters Portal

Browser-based and featuring an intuitive user interface, the Claudius Peters Portal has been designed to take the headache out of troubleshooting, part identification and ordering by linking information from a range of categories and classifications into one simple system to avoid problems traditionally associated with the sae and complexity of technical documents.

Techniks

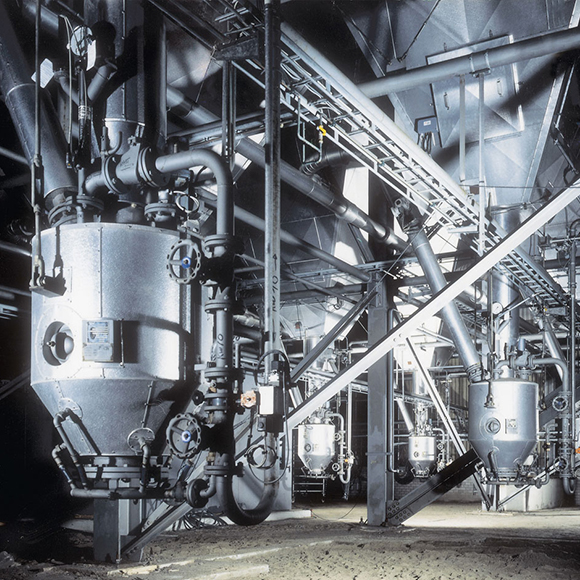

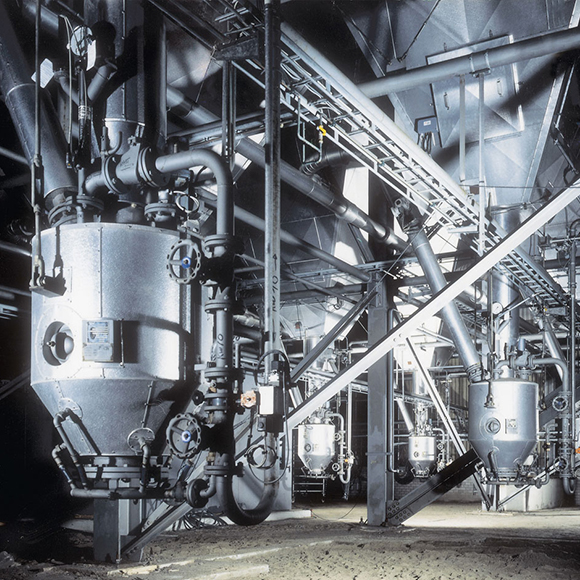

Calcining Technology

Claudius Peters can be your full line supplier for your gypsum processing system.

Clinker Coolers

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process.

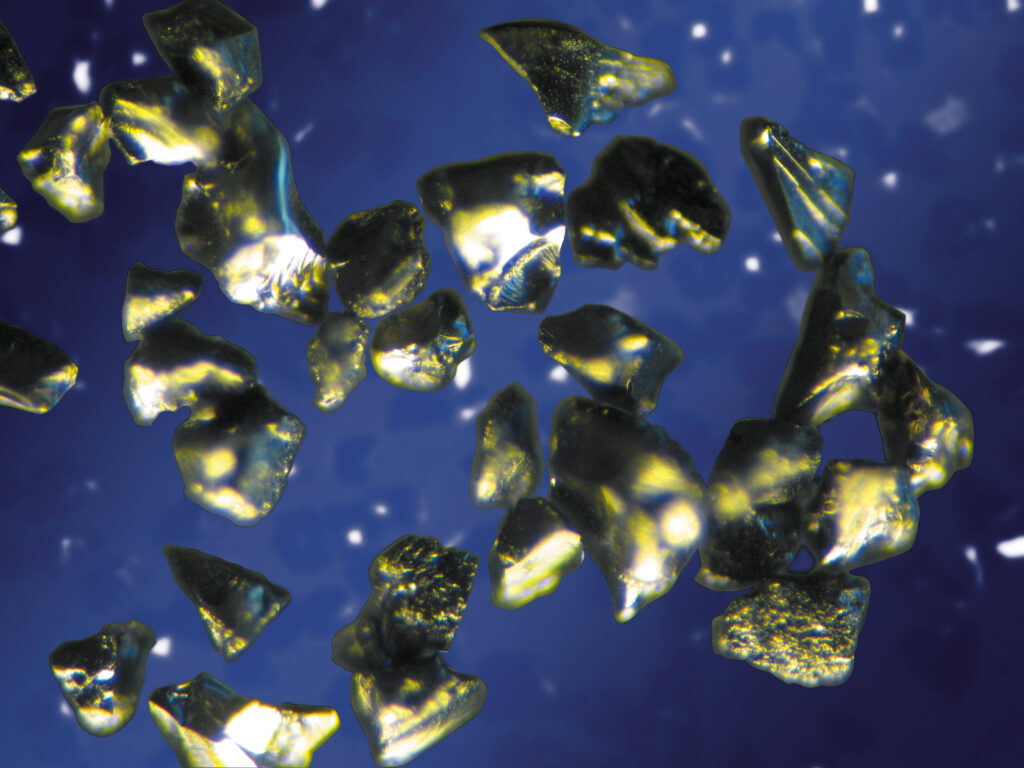

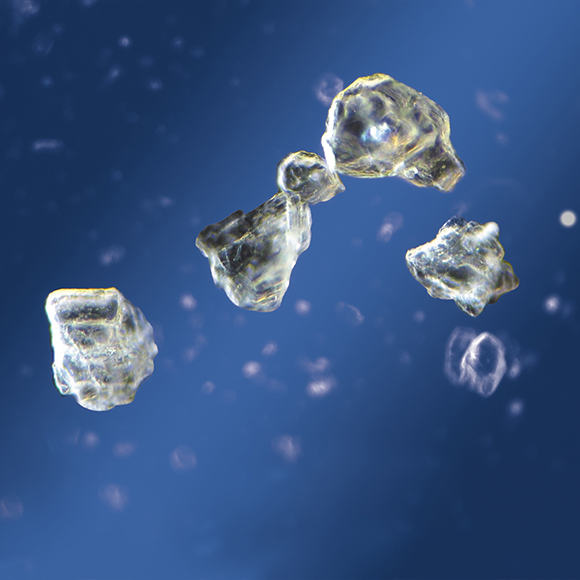

Mineral Grinding Technology

Claudius Peters is widely acknowledged as one of the foremost authorities on coal and mineral grinding technology.

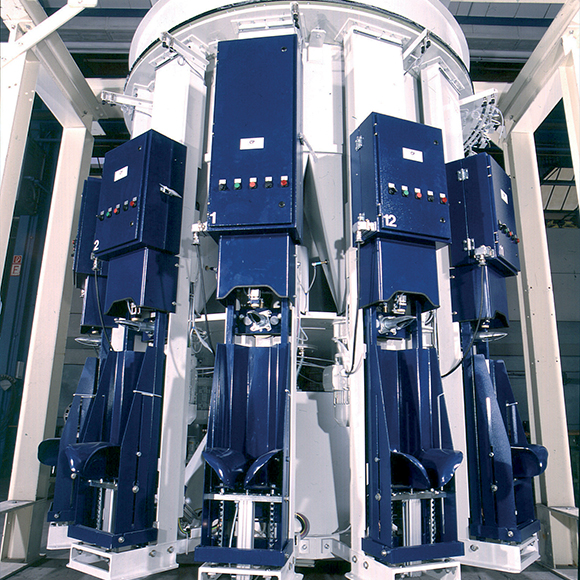

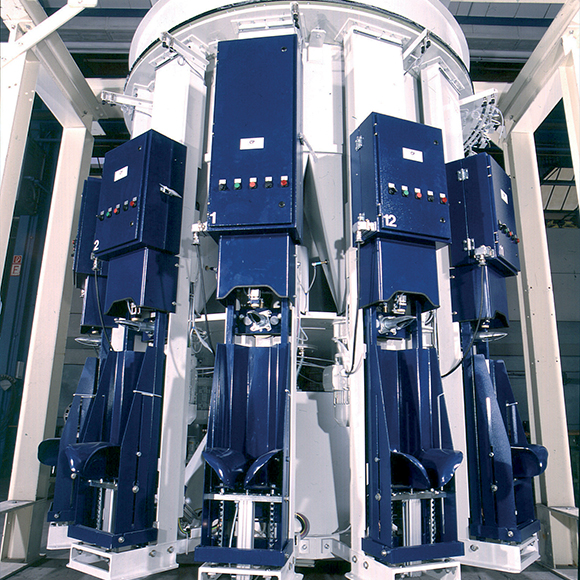

Packing and Palletizing

A large part of the most powerful packers and palletizers in use worldwide today come from Claudius Peters.

Ash Handling

When discussing the energy sources available for the generation of power in addition to gas and oil, the combustion of coal still plays a major role.

Spare parts and service tailored for you

Who else knows your machine as well as we do? We have the perfect support package designed to suit you! Our trained engineers are experts in your machines and ensure genuine parts are used. With same day response, next day delivery for stock parts , we deliver reliability, quality and speed. We offer a comprehensive and growing list of genuine OEM spare parts specific to your serial number to keep your investment functioning at full capacity and maximum productivity.

Sustainability

In the building materials and heavy industry, too, awareness of the need for sustainable action is growing steadily. At Claudius Peters, we feel committed to this claim. We have recognised that it is crucial to minimise our ecological footprint and to assume social responsibility. For this reason, we have taken a number of measures to put sustainability at the heart of everything we do.

Events

View All EventsNews

IFRS Annual Report & Accounts 2023

Langley Holdings plc, the diverse engineering and industrial group, today released its IFRS Annual Report & Accounts for 2023.

Read More

Join us at AUCBM, Cairo

Anticipate an exciting event at this year's AUCBM UACMC conference, set to unfold in Cairo starting Monday next week.

Read More