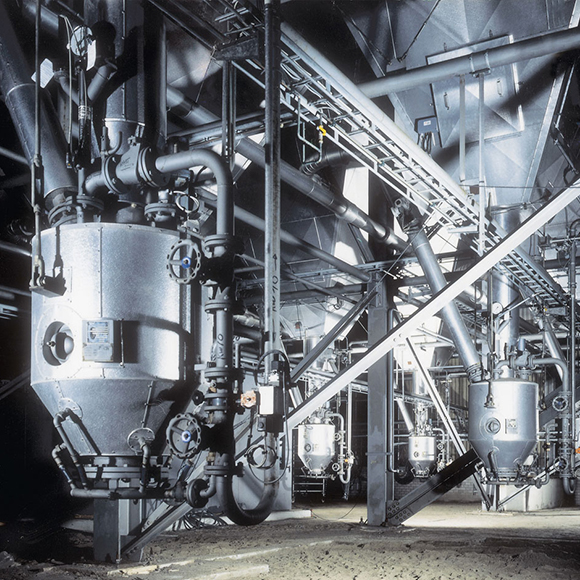

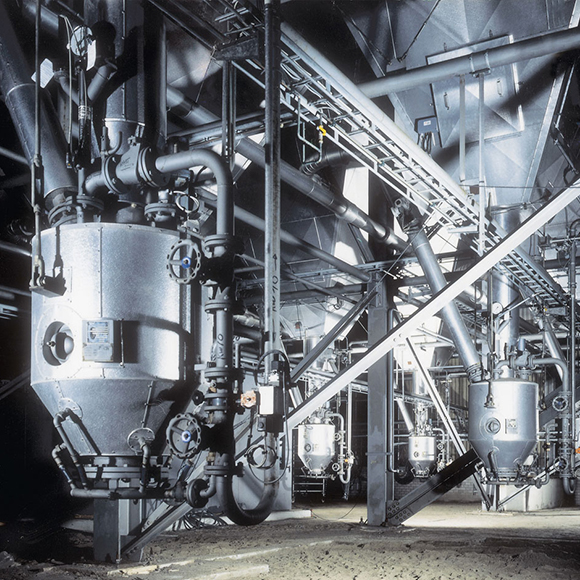

Pneumatic Conveying Technology

As one of the world’s leading names in the supply of systems and equipment for the pneumatic transport of dry materials in large quantities, you would expect us to know a thing or two about innovation, and you would be right. For example, take the legendary Claudius Peters ‘X-pump’ and the ‘aeroslide’ devices, all of which have revolutionized pneumatic conveying.

Claudius Peters FLUIDCON System

Pneumatic conveying has always been an acceptable means for transporting fine materials from one location to the other. The initial investment and maintenance costs are typically lower when compared to mechanical conveying systems, however, the energy consumption for the air supply on pneumatic systems is considerably higher than other technologies’ power requirements.

The Claudius Peters FLUIDCON system has all the advantages of pneumatic conveying but with considerably lower energy requirements, thanks to the incorporation of the aeroslide transportation principle within the transport pipe, providing a dense phase system with increased bulk material load.

With over 80 years experience in the field, Claudius Peters’ Pneumatic Conveying Technik encompasses a broad spectrum of industry. Literally thousands of materials have been tested at our headquarters Technikum (Technical Centre) in Germany, and the company continues to evolve, to innovate and to push the boundaries of what is possible from our systems.

Related Techniks

Ash Handling

When discussing the energy sources available for the generation of power in addition to gas and oil, the combustion of coal still plays a major role.

Clinker Coolers

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process.

Calcining Technology

Claudius Peters can be your full line supplier for your gypsum processing system.