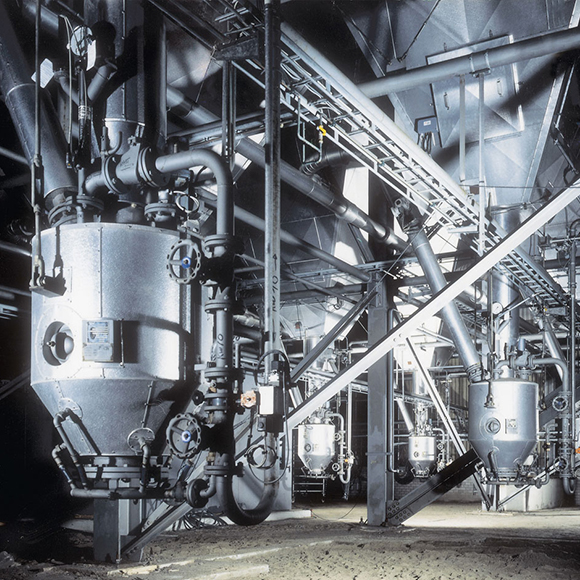

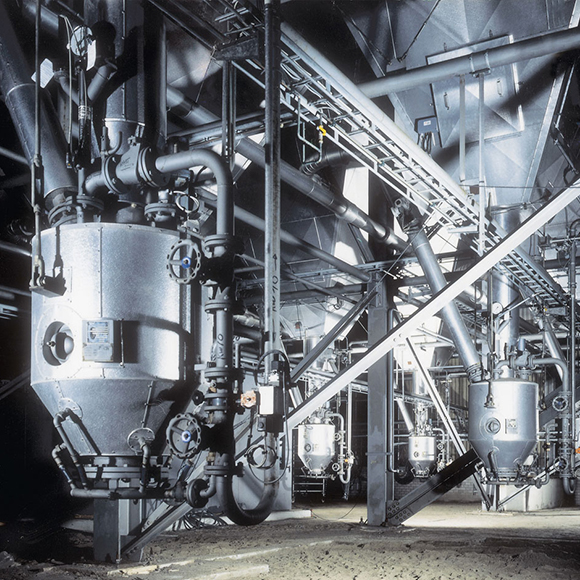

Silo Discharge

With more than 3,000 silo systems sold worldwide, Claudius Peters is a major contributor to the current international standards for silo design.

In addition, the Claudius Peters Technikum (Technical Center) is a state-of-the-art testing and research facility, where the analysis of bulk solids determines the design of Claudius Peters equipment and processes. Developed by Claudius Peters, the expansion chamber principle, along with its patented optional inspection chamber for storage silos and overflow pipes for mixing silos, have become standards in world silo technology.

Techniks

Ash Handling

When discussing the energy sources available for the generation of power in addition to gas and oil, the combustion of coal still plays a major role.

Calcining Technology

Claudius Peters can be your full line supplier for your gypsum processing system.

Clinker Cooling

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process.

Dry Mortar & Mixing

Claudius Peters (CP) is a leading partner for the cement and building materials industry worldwide. Our vast product range is tailor-designed to meet the individual demands of every client, providing a complete solution.

Mineral Grinding Technology

Claudius Peters is widely acknowledged as one of the foremost authorities on coal and mineral grinding technology.

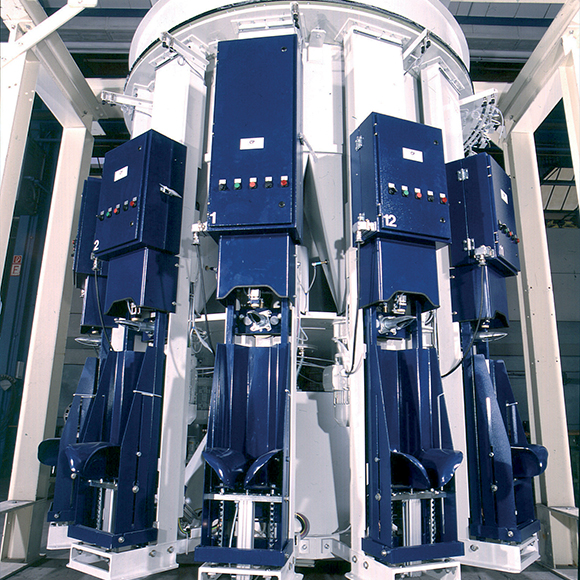

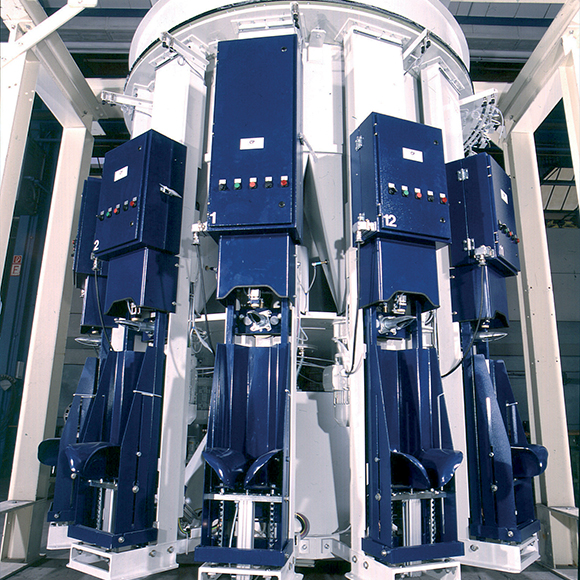

Packing and Palletizing

A large part of the most powerful packers and palletizers in use worldwide today come from Claudius Peters.