Frantoi del Clinker

Frantoi a Martelli

Il frantoio a martelli è la soluzione standard per la frantumazione del clinker. CLAUDIUS PETERS ha fornito frantoi a martelli in tutto il mondo per capacità fino a 6000 t/d dal 1955.

I martelli ruotano a velocità maggiori di 300 rpm.

La parte grossolana del clinker viene frantumata e spinta indietro contro una cortina di catene fino a che le particelle di clinker hanno raggiunto il diametro per passare la griglia dello scivolo.

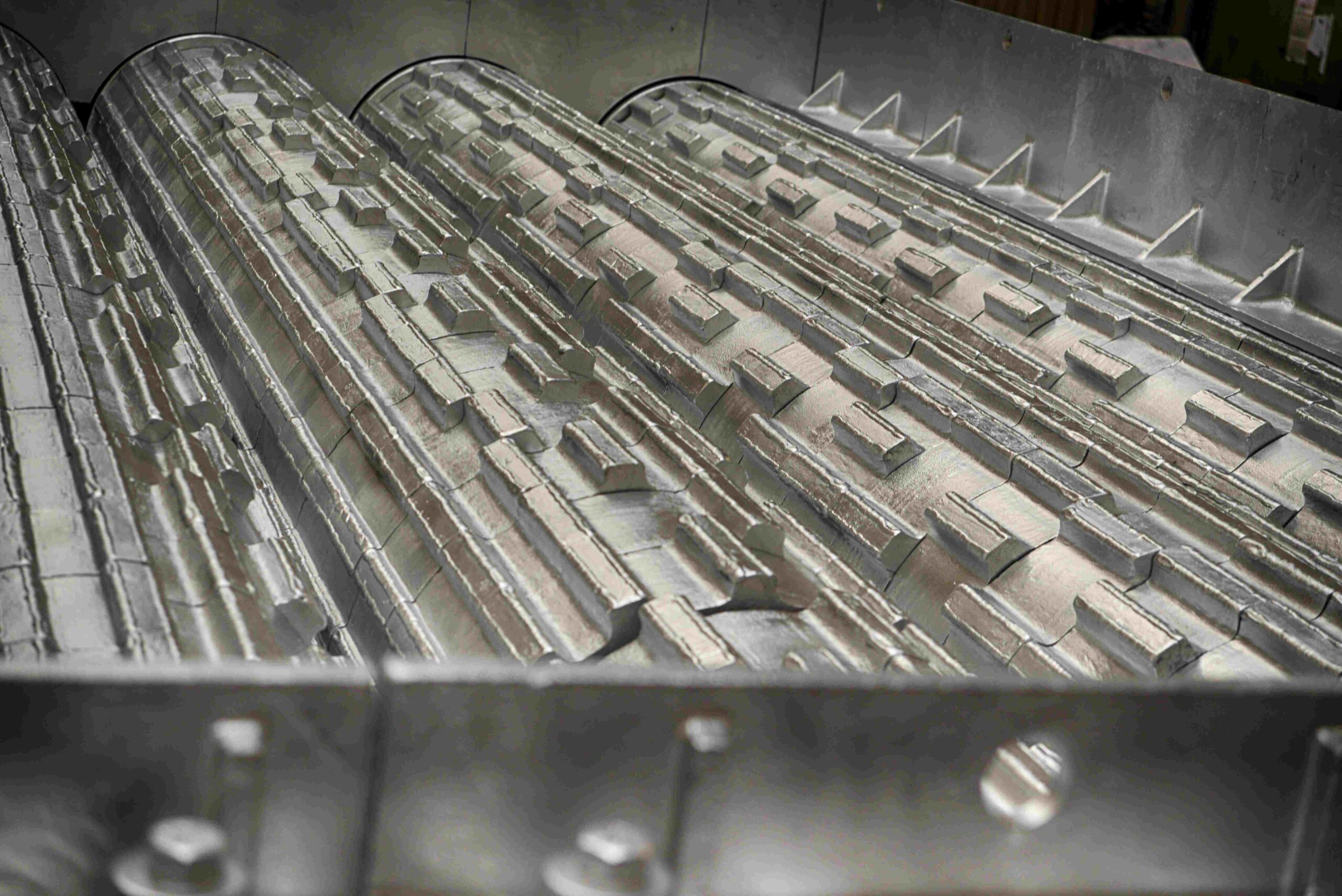

Frantoi a Rulli

CLAUDIUS PETERS ha fornito il frantoio a rulli per frantumare clinker dal 1976. I rulli ruotano ad una velocità significativamente inferiore < 10 rpm e frantumano la frazione grossolana con minore produzione di polvere.

Il comando idraulico, che era utilizzato fino all’incirca all’anno 2000, è oggi per la gran parte rimpiazzato da un comando elettromeccanico o può anche essere fornito come retrofit.

Per raggiungere maggiori capacità, la larghezza del frantoio e il numero di rulli possono essere aumentati.

Il più grande frantoio in esercizio ad oggi raggiunge una portata di 13.000 tpd.

La vita operativa degli speciali anelli di macinazione di CLAUDIUS PETERS può essere enormemente estesa da adeguate misure di manutenzione, cosicchè oggi la raccomandazione per il frantoio a rulli si basa sulle seguenti caratteristiche:

- Maggiore vita operativa

- Ridotta produzione di polvere

- Maggiori portate fino a 15.000 t/d

- Minore consumo energetico

Un beneficio addizionale è la possibilità di esercire il Frantoio a Rulli come frantoio inetrmedio con rulli raffreddati ad aria per raggiungere una temperatura di uscita del clinker uniforme – anche con grandi quantità di granelli grossolani – e di generare più calore per ad es. sistemi di recupero calore (Waste Heat Recovery – WHR) qualora sia attesa una maggior porzione di clinker grossolano.